So, I am expanding the deck on the back of our house and since I am doing it myself and it is a “want to” and not a “need to”, I am doing it slowly, as I get time from other more pressing matters.

I bought 2x8’s from Lowe’s a few weeks ago and got the frame/perimeter built. A week or so ago, I bought more 2x8’s from Lowes to install the support joists. I preinstalled the joist supports so all I would have to do is cut them, drop them in and nail them in place. I measured all 16, cut them and numbered them so I would know where they went since they were not all the exact same length.

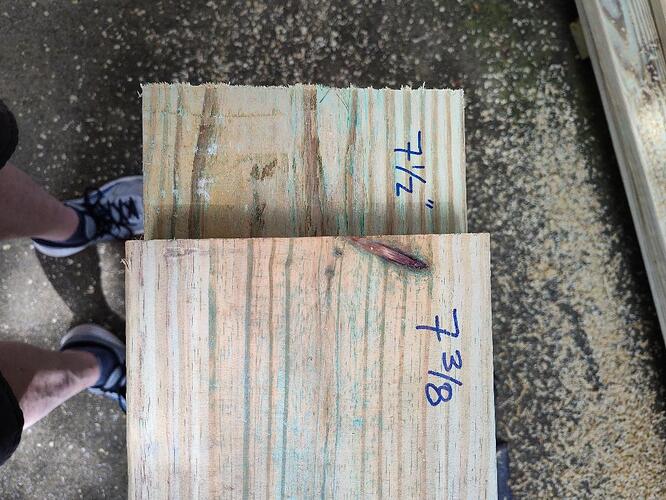

Imagine my surprise when I put the first couple in place only to find that these 2x8’s were actually wider than the ones I bought a few weeks earlier. These are the same brand, from Lowe’s yet they are anywhere from 1/8 - 1/4" wider. Since they were already cut, I could not return them, so I spent more than 2 hours planning them all down to the correct width with a power planner. I have been building things for many years and have never seen this before. I guess you now should measure boards before you buy them now.

1 Like

That’s common, especially, in treated boards, depending on moisture content.

They were probably just delivered, and bands cut. Usually you can tell from the boards being much heavier, with the treating solution still being present.

You could dry stack them for a few days, and they will be much closer to the same size.

Also, that’s why we put the joist hangers on “after” the joists are installed, flush with the top of the band.

Be sure to post us some pics of your progress!!

1 Like

One more point, instead of ripping the entire joist, you could notch the ends, where they sit in the hanger, to keep them flush with the top of the band.

I feel your pain. I have been building raised garden beds, a chicken coop, stairs for the shed, etc and I try to use as much free scrap lumber as I can find on the side of the road, floating in the marsh, etc. thy stuff never matches up exactly…

I thought about notching each board, but my OCD would not let me. It would drive me crazy to see part of the board extending below the support boards. Yeah, I’m weird.

The truth is that all the boards should be the same and there should not be that much of a difference in the size of them.

Anyway, it’s a work in progress and going well. Used a palm nailer for the first time, what a game changer.

Are you getting your deck inspected?

If so, make sure the crossover nails, the ones on the joist side of the hanger, are 3”.

The shorter nails will work on the band side of the hanger.

Inspectors are killing my framers on that small infraction.

There’s a placard on the box that the hangers come in telling what specific fasteners are appropriate.

For the record, I’ve seen as much as 5/8” variance on treated 2x12’s.

Yessir, those palm nailers are a sweet little tool!

Keep us posted on your progress!!

No, no inspection. I try to avoid dealing with city officials anytime I can. I built the original deck, and it has held up well. I plan to tear off the old deck boards and put Trex on the old and the new section.

I tend to go overboard when I build. I have 3/8" galvanized bolts through my supports/posts. I double up on support beams and every joist not only has the Simpson-Strong Tie galvanized hangers and recommended nails but. I also used #14x 6" landscaping/construction screws into the ends of each joist.

I’ll post some pics soon.