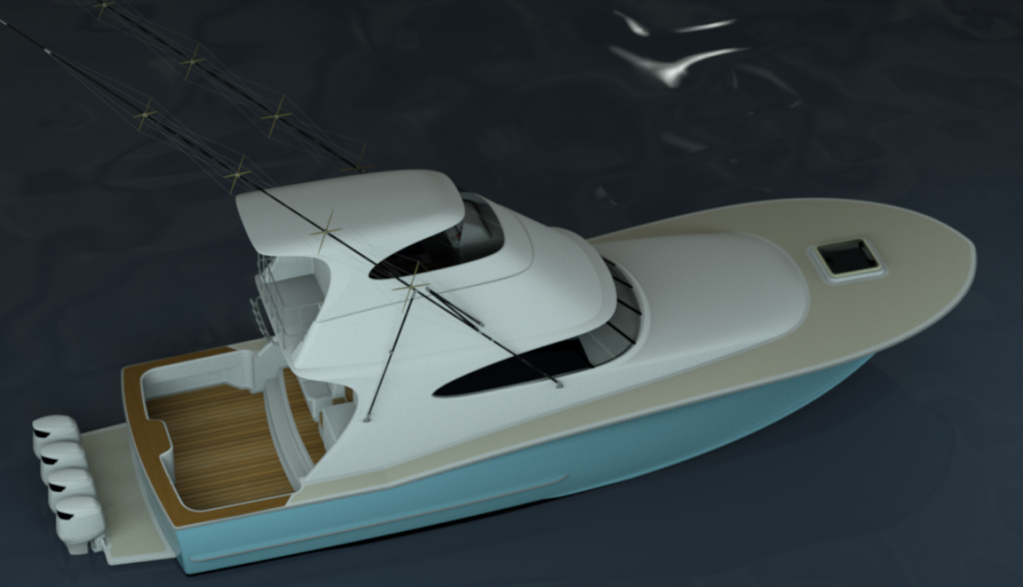

Here is the start of some 3D renders of the boat!

A few Changes: We have stretched the beam to 16’ and also decided to add a Seakeeper Gyro system for stability! Should start cutting ther jig soon.

Here is the start of some 3D renders of the boat!

A few Changes: We have stretched the beam to 16’ and also decided to add a Seakeeper Gyro system for stability! Should start cutting ther jig soon.

Who does your drawings? What software do you guys use?

Do you guys fully model the whole boat before building? Down to what level do you get in detail?

BG

We use Rhino to draw the boats. Yes we completely model the entire boat before we start construction. One of the biggest reasons is to run proper weight and balance calculations which is very important. Secondly, everything has to be drawn in 3D to CNC cut the jigs out to build off of. And of course, we can get a real world look at the boat from all angles to make sure it has the look we are trying to achieve. Thanks for the interest!

Ive never got the chance to design with Rhino, I use Solidworks everyday though. Both are great modeling programs. I wish could design boats instead of machinery. Maybe one day.

1982 MITCHEL CC 18’

1971 NEWPORT DAYSAILER 21’

1970 MAKO CC 22’

quote:

Originally posted by jki4405We use Rhino to draw the boats. Yes we completely model the entire boat before we start construction. One of the biggest reasons is to run proper weight and balance calculations which is very important. Secondly, everything has to be drawn in 3D to CNC cut the jigs out to build off of. And of course, we can get a real world look at the boat from all angles to make sure it has the look we are trying to achieve. Thanks for the interest!

Sorry to ask so many similar questions, I’m an engineer, it’s a built in flaw I have. Do you model cable routing and plumbing? How about TV’s and toilets that you end up installing. Do you consider the weight of the toilet in your calcs? Do you guys fill the wells up with water (weight wise) and fish boxes with fish/ice?

How do you do balance modeling? I’m from way out of town, but I’d love to see all of the engineering side sometime if it was not confidential and somehow I ended up down there when it was convenient.

Rhino will do weight considerations? Do you guys model it dynamically at all, considering pitch/yaw/roll of a weighted boat and the g’s it puts on a person at the helm or other commonly occupied areas?

BG

btodag-

When we do weight and balance calculations we add everything from the fiberglass and resin it takes to construct the hull to the cabinet hardware and light fixtures we choose. It is a very detailed study and takes a bunch of time. Calculations are exact. We simulate it with and without full tanks and based on the CG we know what the boat attitude will do eitherway. As far as dynamically modeling it, in this case we work with outside vendors like seakeeper gyro systems, Yamaha, and Side power thrusters to determine what these products will do to the attitude or responsivness. This specific boat is about a 2 month design process. Not everything is done or figured with Rhino. There are other resources that can help determine structural requirements, lamination schedules, windage, or weight and balance scenarios. Thanks again for the interest!

I will be watching this build thread all the way as I have on the previous builds. Thanks so much for posting them!

I like your series of questions as well Brian. You are a pretty sharp engineer it appears.

I know a couple of engineers that are, as a friend of mine says “educated beyond their capacity”.![]()

![]()

![]()

NN

07 23 Key West Twin 115 Yammys

jki4405 - That about covers my questions. Thanks. It sounds like a really amazing company/process. I wondered if the vendors of gyro systems would do that kind of stuff for you trying to sell it to you or if they would at least provide some really killer info for cheap in an attempt to sell it.

One last one… Have you guys ever done an as built actual data collection to see how the pitch/yaw/roll, etc actually performs vs the projections or do you just get on it and talk about how sweet it turned out at that point? I’m sure I’d be talking about how sweet it is instead.

NN - That’s me, got more paper saying I “should” know things than I really do.

BG

The craftsmanship itself is amazing, but it’s exciting for me (and I suspect a few other nerds out there) to see that same level of detail and care applied to the engineering aspects of the design as well. You guys obviously have some pretty solid engineering education and/or experience, if I could apply my ME degree to something half as cool someday I’d be a happy man!

Thanks for the inspiration, keep up the good work!

Angler 204 FX

Yamaha 150

quote:

Originally posted by wolfie ...if I could apply my ME degree to something half as cool someday I'd be a happy man!Thanks for the inspiration, keep up the good work.

</font id=“quote”></blockquote id=“quote”>My thoughts exactly. I was drawing/designing 3d models of equipment in 1997. I was the young guy and quick with software having tons of fun. Back then impressed everyone that you could rotate things, check clearances, etc. I was younger and seems like I remember rendering everything in some form of chrome… pimping it out for the wow factors of the renderings. To see models of fluid shapes such as a boat always impresses me and a maturity of design is so impressive. I miss those days sometimes. I used to get really excited to see electrical panels or extensive piping plans that were detailed out in 3d.

As much as reasonable, give us model updates as eye candy of what’s to come. I keep dreaming of a hard top with a MFD in the back of it like the last build. That’s one of the many awesome things from that boat.

BG

We finished setting up the new router today and we are ready to start cutting the jig for the 48’!

So…in the past you have had someone else cut the jigs for you, but now you’re cutting the jigs yourself?

That is correct

I guess I am a purist and an old “stick in the mud”…I just don’t like outboards on a boat like this. Undoubtedly there’s a market for a 46’ convertible with outboard power, but I will always like a clean transom.

FWIW, I would think this boat is an ideal candidate for diesel pod propulsion.

Good luck on the build!!

“Never argue with an idiot…he will drag you down to his level and beat you with experience.”

On the way back from Miami now back to the shop to finish cutting the jig.

Wolakrab-

We would love to do a pod boat! Who knows? That might be next!

Do you guys already have a buyer lined up?

We are about 1 week into the build now and its coming along nicely! You can already see the lines.

It looks like you guys are integrating the stations into the structure of the hull this time. Is that for strength / structure or just easier than trying to remove frames after? And I am assuming that previous builds with the blue tape were to facilitate removal? You guys are living my dream, thanks for the updates and progress reports!

Other than the blue tape this is the same way we always do it. All the stations/jig pieces will be removed after we flip the boat. The Doug fir keel, stringers, Chine, and sheer band you see will stay with the boat.