note: been working on this for a little while, going to cut and paste previous post from other sites to get up to date here

Hey guys - I’ve followed various builds on this site for years, and I finally am at a point where I have the time to pursue one myself. I love the idea of taking something old and making it new again, exactly the way I want it, and the Mako community made the decision pretty easy.

I have a boat already, but I have found that I am always improving things and adding upgrades, but it was getting to the point where the boat wasn’t really worth putting the time and $ into ('06 Angler 204, despite the bad rap not a bad beginner boat in my opinion, but definitely not something I wanted to keep forever.)

I wanted a 22-25 boat that I could outfit the way I wanted, big enough to get offshore a little ways but shallow enough to fish the bays, and comfortable enough to keep the family happy. Well, those boats definitely exist, but I don’t have $150k to drop on one…

After a LOT of research, reading every post of the Mako History Q&A thread about three times, countless discussions on this site and others, I decided that the 224 and derivatives (221, 231, etc etc) would be the perfect platform to start a “custom” rebuild of a classic. Since I was looking for a pretty specific hull (the 231 was my first choice) I was afraid I might either be looking for a while or compromise, but then got a tip off that this girl was available:

1986 231

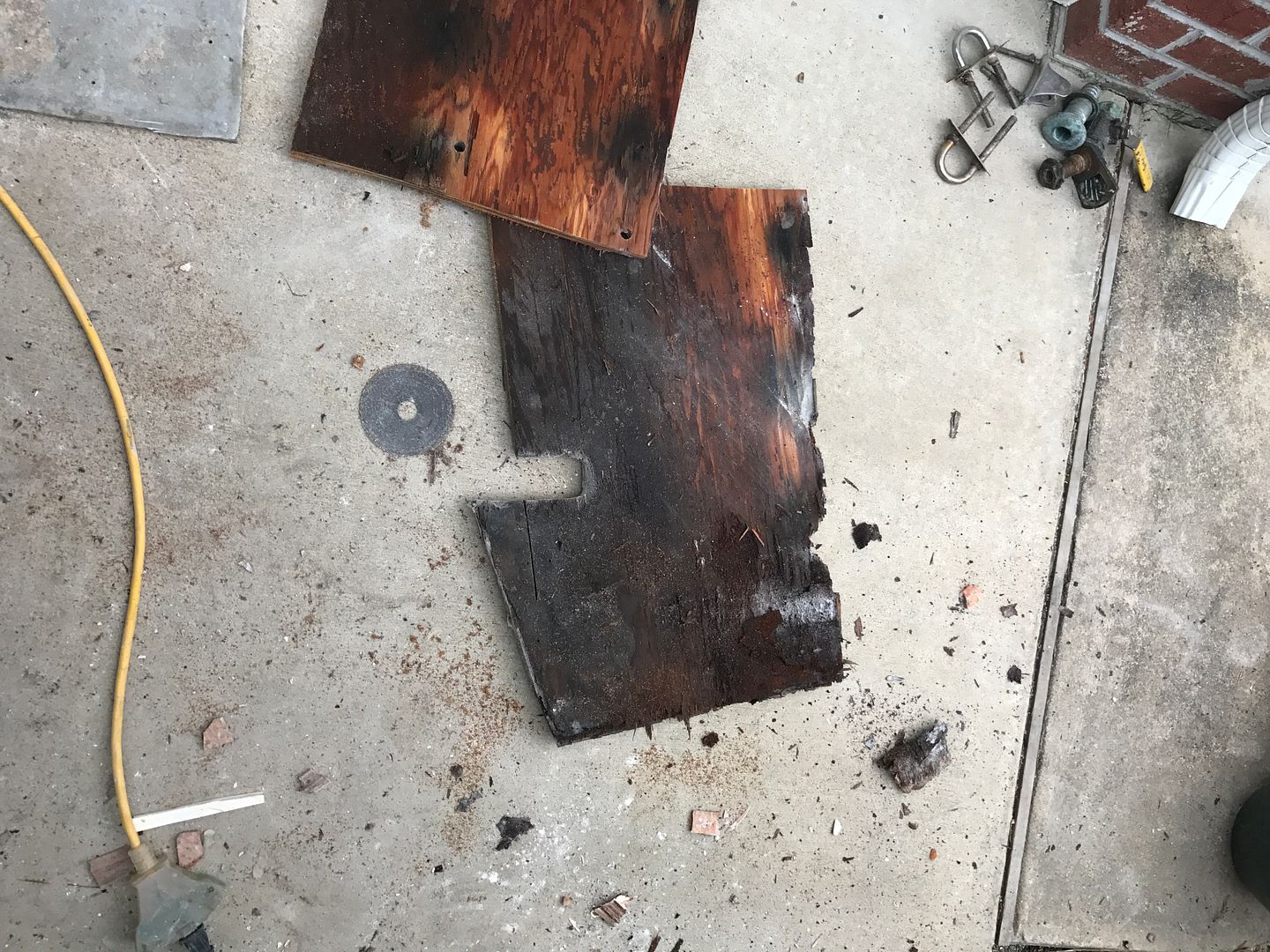

listing suggested the boat had already been partially restored, solid decks, new tank, and was essentially ready for paint, with a working trailer. Turns out maybe not quite true (more to follow on this…) but hull generally sound and exactly what I was looking for so I went for it anyway.

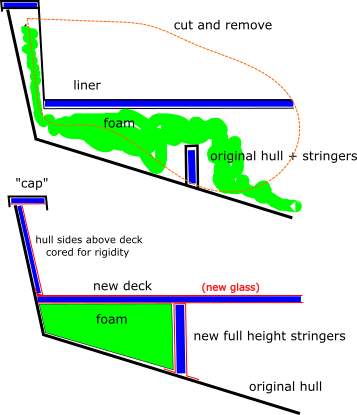

So here we go. I am still in the planning stages, but I have a lot of ideas for what I want and my goal is to incorporate everything on my “boat wishlist” in this build. ![]()

Som