Looking great man. My time off has been limited. Maybe soon.

2000 2220 KeyWest CC 225ox66 “Drippin Wet”

Looking great man. My time off has been limited. Maybe soon.

2000 2220 KeyWest CC 225ox66 “Drippin Wet”

work remaining

paint bilge beam and bilge areas

.

attach bilge beam and macerator valve selection box and plumb

.

mount fuel filter, gauge, water witch sensors, pumps, wiring conduits, etc.

.

Plumb transom livewell

.

extend cockpit aft walls to integrate with livewell and gunnels

.

close up back of false transom over splash well

.

design console interior drain area with outlet Teeed into anchor locker drain line

glass console base interior to stringers and bulkhead

.

modify/strengthen console

cut out console doorway hole

install console

.

glass undersides of new mid ships gunnel areas

.

recore fwd fish box lid and finish underside smooth

.

fwd livewell and drain seacock installation

fwd deck and fwd seating sections replacement

.

fwd seating area/repair

.

modify T top electronics box for speakers and flush mounted VHF’s

.

sand transom area

sand, fill and fair deck

sand interior of boat from rub rail inboard

.

regelcoat running surface

.

Paint/lineX prep

paint/lineX

.

rigging/building

.

adjust trailer bunks

replace trailer wheel hubs and winch stand

Luke 8:22-25

MOJO,

good luck on the overhaul. I did my 84 20Mako awhile back. Classic Mako is the best. I did it while I was in Pensacola, my thread was overhaulin 20c something like that. I actually had Wart help me out with most of it. Let me know if you need anything.

TED>

quote:

regelcoat running surface

You mention the above.

Are you gonna apply new gelcoat over the old GC on the bottom of the hull?

If so, how are you gonna apply it?

quote:

Originally posted by RDWquote:

regelcoat running surface

You mention the above.

Are you gonna apply new gelcoat over the old GC on the bottom of the hull?

If so, how are you gonna apply it?

Original gelcoat is thin after all the cycles of bottom paint.

Most of it will get sanded off before spraying new and then polishing it…

Luke 8:22-25

Keep up the good work, Wes. Hope the move (and the million other things you have going on) went okay. Holler at me when you have a second.

“I’m not a hundred percent in love with your tone right now…”

Looks like crap. Hurry up and get it finished!

How’s that for motivation?

Rapchizzle, please study this diagram.

There will be a test later.

Luke 8:22-25

Wes, with the “Sea Chest” are you using Tsunami Bilge pumps? Have the same bait tank on my 197 and am having trouble with air locking. Have pulled all the piping loose, made sure no clogs from sealant, shortened the hose run from pump to tank to ensure no low piping. I has improved but am still on occasion loosing prime. Did you make the box yourself? I am very tempted to do the same thing in my boat.

quote:

Originally posted by onealWes, with the “Sea Chest” are you using Tsunami Bilge pumps? Have the same bait tank on my 197 and am having trouble with air locking. Have pulled all the piping loose, made sure no clogs from sealant, shortened the hose run from pump to tank to ensure no low piping. I has improved but am still on occasion loosing prime. Did you make the box yourself? I am very tempted to do the same thing in my boat.

Your 197 has sort of a hybrid cross between a sea chest and straight thru hulls for each raw water need. I may be mistaken, but I believe your Pioneer has a starboard grate over a recessed water box that they mold into the hull. Sort of a pocket. Then you have thru hulls for each pump or intake in the roof of that pocket.

You’ve got a regular aerator pump and thru hull that has to lift water to itself then lift it to the livewell. The system you see above is using bilge pumps that stay submerged underwater inside the seachest. They should never lose prime because the pumps stay underwater. I am worried a little about how the fwd livewell does because that line does dip down from the pump to run under the port fish box and up to the fwd livewell. I don’t plan on using the fwd livewell except while fishing though (not while underway) so I think it will work well enough.

To put a sea chest in a 197, I’d have to head scratch a little while and think about how the boat’s built. It may be the 220 baysport I’m thinking about with the pocket in the hull. Doesn’t your 197 have that area I’m describing?

Luke 8:22-25

There is a low spot in the center of the bilge where the Bilge pump sits. I guess what I need to know is where the water line is to determine where I could mount the sea chest. I feel like it is 6 to 8 inches above the through hull where the bait pump is attached. There is a flat spot on both sides of the bilge where a battery tray is often mounted on the starbord side and a duplicate flat spot on the port side where raw water wash pumps would be mounted. Thinking of piping from the now bait pump through hull into a box mounted on one of these pads. Im thinking as long at the water level is higher than the sea chest box than I should be good.

quote:

Originally posted by onealThere is a low spot in the center of the bilge where the Bilge pump sits. I guess what I need to know is where the water line is to determine where I could mount the sea chest. I feel like it is 6 to 8 inches above the through hull where the bait pump is attached. There is a flat spot on both sides of the bilge where a battery tray is often mounted on the starbord side and a duplicate flat spot on the port side where raw water wash pumps would be mounted. Thinking of piping from the now bait pump through hull into a box mounted on one of these pads. Im thinking as long at the water level is higher than the sea chest box than I should be good.

The deeper you can get it, the smaller the thru hull and valve you will need for the same flow as with a higher chest and bigger plumbing.

Sometimes less is more.

You have one livewell and a washdown pump, right?

You should not need more than one 1" sea cock feeding a chest. I still am not sure you couldn’t fix your problem with some tweaks to your current system.

You have standard options on your 197SF?

Luke 8:22-25

Oneal, you need a bigger pump and different than the setup where the livewell and washdown are on the same through hull. Same problem on the 2012 222. They separated mine then had to change the Livewell pump to a bigger size and configuration.

Wes, the 222 has a pocket built in for the pumps.

Mark

Pioneer 222 Sportfish Yamaha F300

Yeah, but do you consider a dog to be a filthy animal? I wouldn’t go so far as to call a dog filthy but they’re definitely dirty. But, a dog’s got personality. Personality goes a long way.

“Life’s tough…It’s even tougher if you’re stupid” John Wayne

There is a built in pocket on the underside of the hull as you described, covered by a peice of Starboard. I have the raw waterdown option so there are 2 through hulls going into that “pocket”. Each through hull fitting has a brass ball valve. The Raw water goes to a Shureflow pump that I dont have any issues with. The second through hull has an Attwood Tsunami 500GPH pump. I think one of the bigest issues was on the discharge side there was a loop in the tubing that was acting as a trap. I have removed the loop and it is much better but i have had the pump stop pumping. There is a loose coorilation to backing down/reversing and I stress the word loose. I have not witnessed the exact time that it stops pumping. I did not have this problem with the 197 Venture and it was piped almost identical.

quote:

Originally posted by onealThere is a built in pocket on the underside of the hull as you described, covered by a peice of Starboard. I have the raw waterdown option so there are 2 through hulls going into that “pocket”. Each through hull fitting has a brass ball valve. The Raw water goes to a Shureflow pump that I dont have any issues with. The second through hull has an Attwood Tsunami 500GPH pump. I think one of the bigest issues was on the discharge side there was a loop in the tubing that was acting as a trap. I have removed the loop and it is much better but i have had the pump stop pumping. There is a loose coorilation to backing down/reversing and I stress the word loose. I have not witnessed the exact time that it stops pumping. I did not have this problem with the 197 Venture and it was piped almost identical.

I had the same pump, it was replaced with an 800gph pump and no issues yet. Same thing about losing prime before that you are having. Should be a warranty issue if you take it in to the dealership.

Mark

Pioneer 222 Sportfish Yamaha F300

Yeah, but do you consider a dog to be a filthy animal? I wouldn’t go so far as to call a dog filthy but they’re definitely dirty. But, a dog’s got personality. Personality goes a long way.

“Life’s tough…It’s even tougher if you’re stupid” John Wayne

I agree with Mark.

You probably burnt your aerator pump a little due to air locking. The loop in the hose likely was the culprit. Dealer should give you a new pump.

You will get cavitation from the prop inside the pocket when reversing hard. Normally a little air is good for your bait. So much where you air lock isn’t what you should be seeing, and they’d fix it under warranty I’m sure.

You can stick your washdown hose in your splash well with the trigger engaged to constantly purge the air from your pocket…

I would do this if bait health is critical and it’s a rough day on the ocean (like the old Phin used to be known for). ![]()

I don’t remember ever having a problem with bait pumps on all the 197’s I have fished.

Luke 8:22-25

Thanks guys, didnt mean to derail your thread Phin. Boat looks good, keep the photo’s and progress coming. I have a spare insert for the pump, may try that and if I continue to air lock, I’ll consider going to the 800gph that was the cure for your 222, Salty.

New design for the stern corners. I think this will look lots better. A friend of mine recommended I try this with a mold he is not using right now. He showed me how to use the mold, and I splashed up a section to just get a visual. I will make the full versions this afternoon with a high density core section for the cleat in each side.

Luke 8:22-25

Here is one side of the mold that I used

Cutting cloth by using the splash as a guide. Just flip cloth over to cut out mirror images for the other side

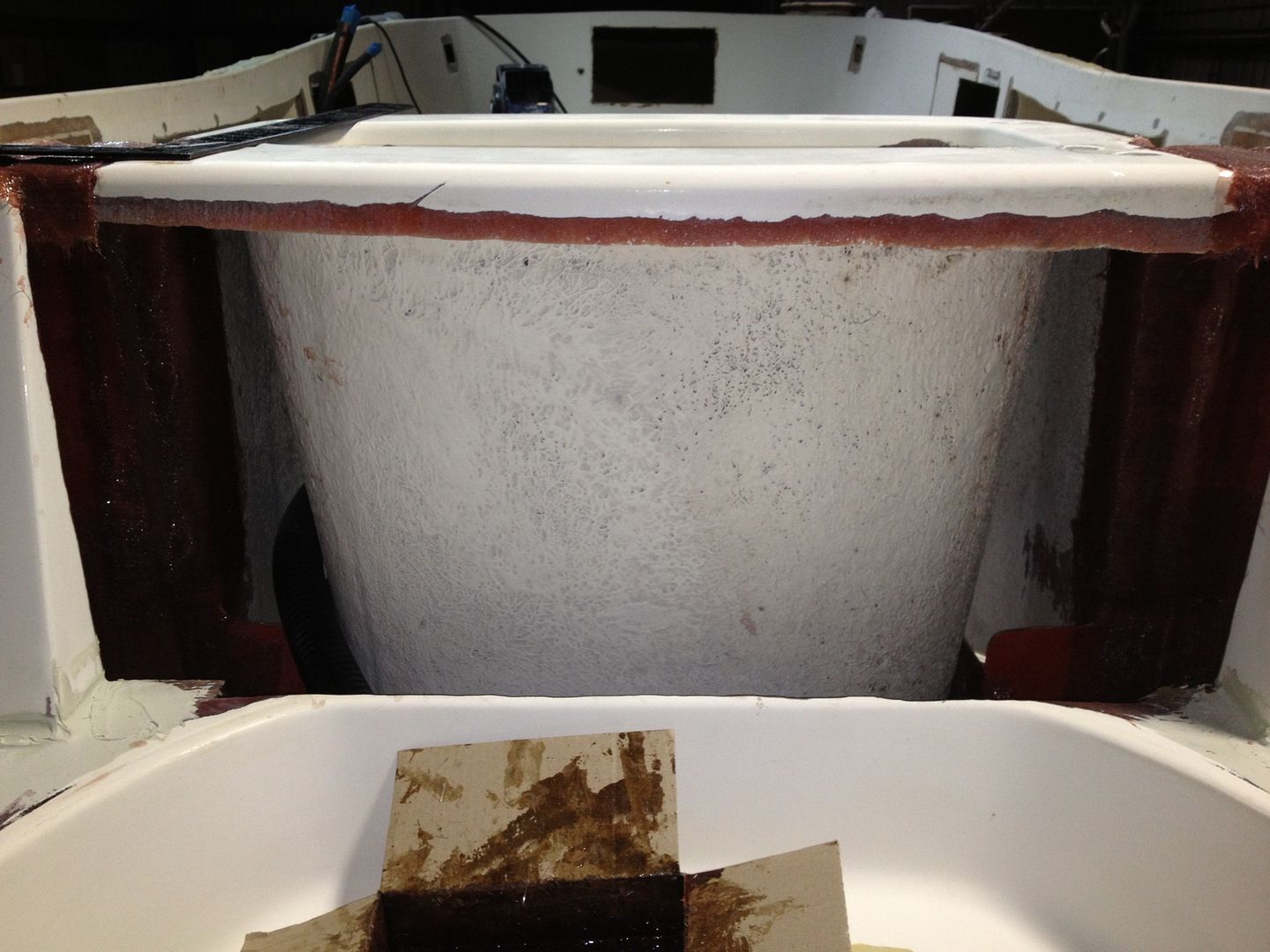

Permanent starboard side piece after I laid it all up. high density coring where the stern cleat will mount.

before trimming it

thought of a way to save time making big radius areas where the above pieces will join to the deck and false transom- used 3" thin wall pipe to make smooth radius pieces

cut in half, and they pop right off

both pieces done. starboard side came out better because I put thickened resin in first and let it kick off.

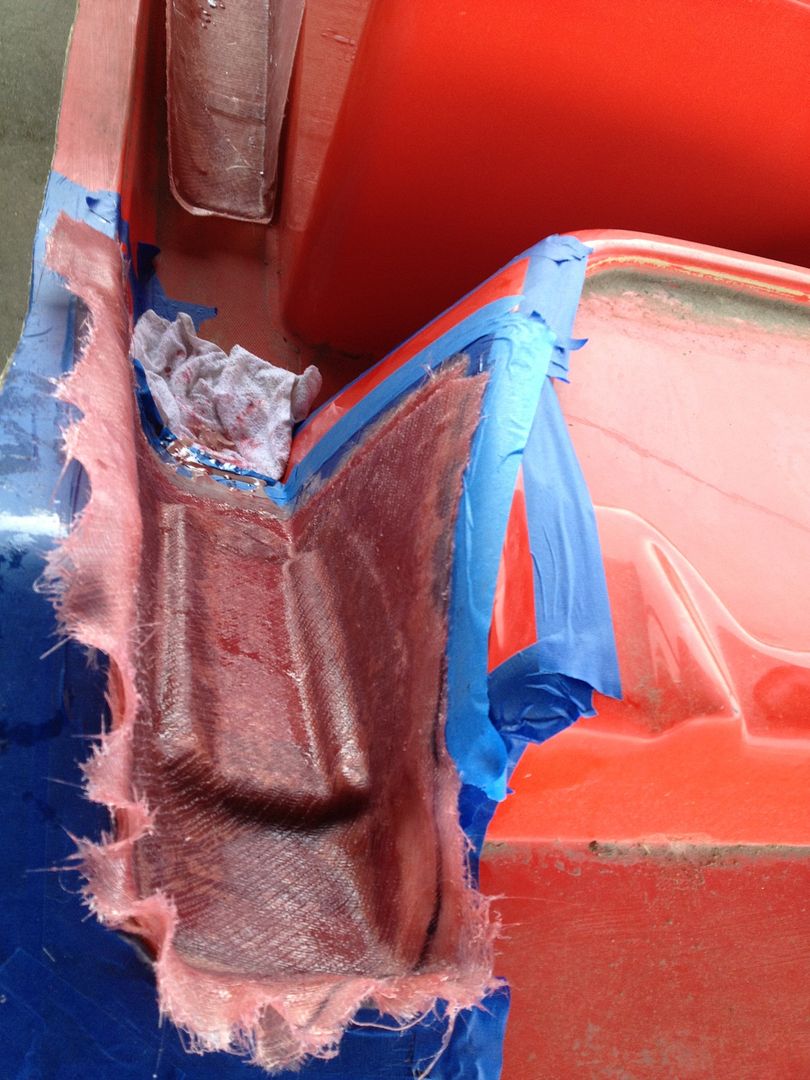

put more glass on the livewell facia and cockpit wall joint

Luke 8:22-25