Let me know when you want to open a shop. Top notch work there my man. I like the stick trick for patterns. Keep on keeping on.

thanks for the words of encouragement. i’m definitely not a professional in the sense that I get paid to do anything like this, but I like to believe that doesn’t stop anyone from getting “professional quality” results with a little homework and determination.

power’s out in the building at work today, so got a few bonus hours to work on the boat! going to start attacking the liner and decks.

Angler 204 FX

Yamaha 150

power was out in the building at work today, so got a few bonus hours to work on the boat!

Now that transom in solid again, I am moving forward with the next phase, which will be to remove the liner to access the stringers.

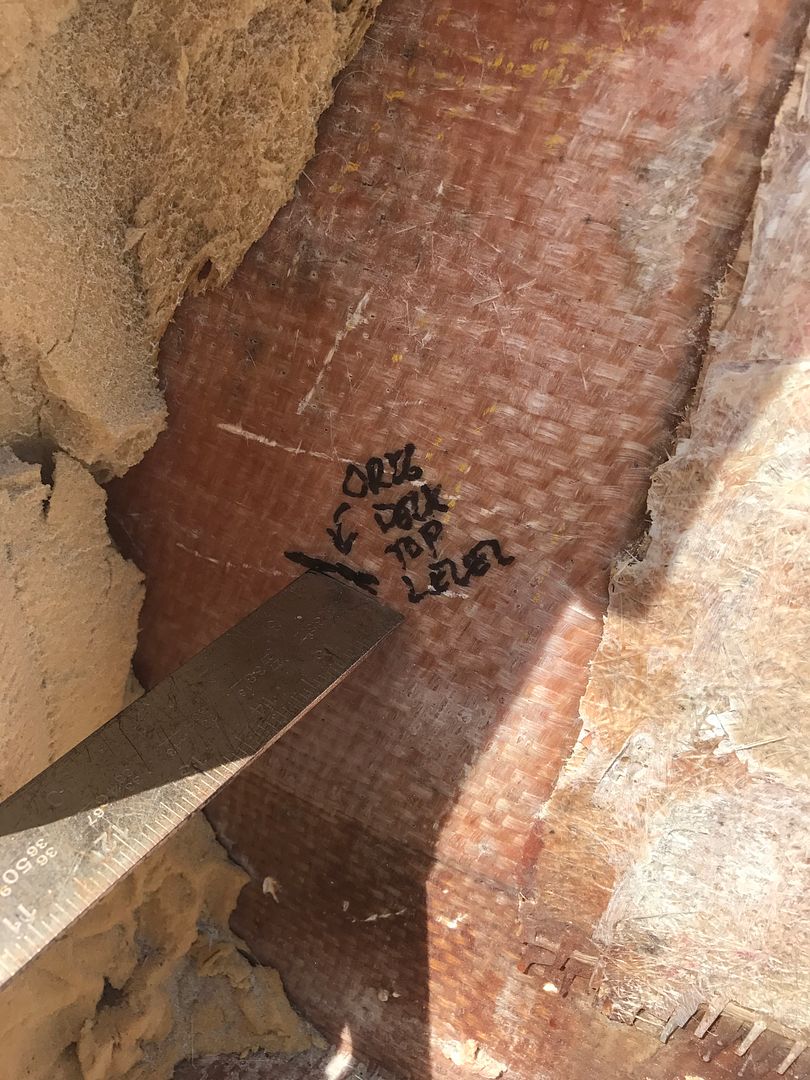

marked and measured original deck level, layed out some lines and then back to cutting…

I left about a 4" lip around the coffin, since I might reuse that wanted to leave some glass to work with. Measured down 6" from to of gunnels to leave enough lip on cap. Then basically cut out everything in between.

starboard deck had a vertical stiffener, pure luck that I missed it with my cuts but worked out well. ![]() Deck is held down by a loose, crappy twist of roving that took a little prying to break.

Deck is held down by a loose, crappy twist of roving that took a little prying to break.

stiffener had a semicircle cut out for the pvc chase, not sealed at all and completely gross. Looks like there may have been a metal strap or something that has long since disintegrated? contributed to a lot of funk in the foam

port side wasn’t as easy to get up because of chase for fuel fill line. Eventually was able to work it loose and pry up deck section.

[img]http://i1187.p

Try a hand adz on that foam it realy does the trick!

We have used Coosa on our deck re build on a 46 Davis express. Worked great.

an angle grinder with a cup style wire wheel will disintegrate the foam instantly on contact

works great for removing foam in smaller areas

www.teamcharlestonmarine.com

www.joinrfa.org

IF I RESPOND IN ALL CAPS, ITS NOT ON PURPOSE, AND I AM NOT YELLING

quote:

Originally posted by boatpoorTry a hand adz on that foam it realy does the trick!

hmm, thats not a tool I currently have in the arsenal. thought about a pick axe but decided that might be overkill… ![]()

quote:

Originally posted by chris Van angle grinder with a cup style wire wheel will disintegrate the foam instantly on contact

works great for removing foam in smaller areas

www.teamcharlestonmarine.com

www.joinrfa.org

IF I RESPOND IN ALL CAPS, ITS NOT ON PURPOSE, AND I AM NOT YELLING

that i do have, great tip!

Angler 204 FX

Yamaha 150

foam removal continues.

there is a lot of foam in these boats.

found a colony of ants or maybe termites, that was exciting.

Most of the foam was pretty dry, but a few areas where it was totally saturated. Water poured out like from a sponge when i stabbed it.

more foam.

did i mention there is a lot of foam?

good thing tomorrow is trash day!

getting there though.

Will pop the coffin out and clean up the last bit of foam in the main part of boat, then tackle removing the bow seating/boxes complex.

Angler 204 FX

Yamaha 150

if you are not going to change the bow layout, why would you remove that section?

www.teamcharlestonmarine.com

www.joinrfa.org

IF I RESPOND IN ALL CAPS, ITS NOT ON PURPOSE, AND I AM NOT YELLING

quote:

Originally posted by chris Vif you are not going to change the bow layout, why would you remove that section?

www.teamcharlestonmarine.com

www.joinrfa.org

IF I RESPOND IN ALL CAPS, ITS NOT ON PURPOSE, AND I AM NOT YELLING

i could probably get away without pulling it, but I plan to totally redo the stringers and seems like that would be easier to do with the boat entirely open. Also, I have no idea how much of that section is cored, but every bit of wood in this thing has been wet and so I’m sure any wood up there is too and I want it gone. If I’m going, I’m going all the way!

hopefully, I will be able to cut out all the bow seating as one big chunk, flip it over and recore, and reuse without too much modification.

Angler 204 FX

Yamaha 150

quote:

Originally posted by wolfiequote:

Originally posted by chris Vif you are not going to change the bow layout, why would you remove that section?

www.teamcharlestonmarine.com

www.joinrfa.org

IF I RESPOND IN ALL CAPS, ITS NOT ON PURPOSE, AND I AM NOT YELLING

i could probably get away without pulling it, but I plan to totally redo the stringers and seems like that would be easier to do with the boat entirely open. Also, I have no idea how much of that section is cored, but every bit of wood in this thing has been wet and so I’m sure any wood up there is too and I want it gone. If I’m going, I’m going all the way!

hopefully, I will be able to cut out all the bow seating as one big chunk, flip it over and recore, and reuse without too much modification.

Angler 204 FX

Yamaha 150

GO MAN!!! Do it right. You’ll have something of value, that you made, instead of a production hull. Your ability isn’t limited. Do the stringers right and the rest will follow. Turn a great hull into your most functional ride. Make it a pleasure to be on…and easy to work.

I also want to know how much you pay for garbage pickup? Whatever it is, you getting a deal.

makes sense

www.teamcharlestonmarine.com

www.joinrfa.org

IF I RESPOND IN ALL CAPS, ITS NOT ON PURPOSE, AND I AM NOT YELLING

quote:

Originally posted by mdaddyI also want to know how much you pay for garbage pickup? Whatever it is, you getting a deal.

yeah buddy, and I got five more bags ready for the garbage man today!

Angler 204 FX

Yamaha 150

Dear Mako,

Please stop with the !@#$%&* foam already!

Thanks!

Got the coffin out today, boy was there some awesome stuff waiting for me under there. The smell of this foam was so alien and terrifying I can’t even begin to describe it, but it will haunt my nightmares.

Got the bow cut laid out and made, still have some connections to break but getting pretty close. Turns out the anchor locker is a separate assembly, so have to figure out how to separate that from rest of seating.

Angler 204 FX

Yamaha 150

decks are out! finished up cuts between front seats, cap, and anchor locker. Mini air saw was the tool of the day. If you’re working on a boat and don’t have one, get one!

the side liner pieces are attached to the rest of the liner with a single layer of mat, so a few strategic cuts and that was loose.

anchor locker is bonded to cap, and rear bulkhead is bonded to seating assembly so had to cut that out. Don’t think i will be reusing anchor locker in original config anyway so not too worried about it, and I can always fix later if needed.

After a little prying and lifting each corner with a jack the seating assembly popped free! (please excuse the support for my ghetto boat cover running through the middle of photo)

dear god, it never stops: more foam removal ensued. between the last round and today 13 more bags for the trash man, bringing the total (i think) to 25.

So I think I figured out what the mysterious loops of roving I’ve encountered a couple of places are for. Found this weird artifact in the forward bilge, and had a “duh” moment: I think they must be for lifting the hull or liner from the mold. as a side effect, they do a pretty (**() good job of anchoring the piece they’re attached to into the mass of foam.

Also, if you have anchor locker drain problems, it’s no (**() wonder. I’m sure a convoluted run of 3/4" pvc seemed like a fine idea, but mine was packed with mud and crap. g

Is the boat on a trailer or on jacks/blocked? The hull bottom will distort when you cut out the stringers I believe. Just saying to be aware.

I can’t believe they are taking the bags of foam. We can’t take it to our local dump…IN BAGS!!!

quote:

Originally posted by mdaddyIs the boat on a trailer or on jacks/blocked? The hull bottom will distort when you cut out the stringers I believe. Just saying to be aware.

I can’t believe they are taking the bags of foam. We can’t take it to our local dump…IN BAGS!!!

well, they may not exactly know what’s in the bags… and as long as they keep taking them I’m not asking too much about the rules!

boat is on a trailer, and I need to keep it portable so yeah bracing it is going to be a problem. Think I may build up the trailer into a sort of cradle, with some lateral support instead of just the bunks. still working on it.

I’ve also considered trying to rent some shop space, which would be simplify a lot of things but just too much $$ for everything I’ve found so far. still looking though.

Angler 204 FX

Yamaha 150

Great looking work. One thought before you cut out anymore structure. If you’re going to remove bow to do stringers, be aware that your hull will sag if it does not have some support. Do something real to keep the shape of the hull intact while you’re doing the stringers and until you have substantial structure built back it. The outer hull laminate will not be stiff enough to keep its shape. Also, remember to think about both bow-to-stern and side-to-side directions. You don’t want the line of the keel to bend or twist and you don’t want the sides to sag. You don’t want the geometry of your hull to get wacky. She needs to stay reasonably symmetrical or you could end up with some odd handling characteristics.

Never mind. Wrote that while looking at page 2 of the thread. Mdaddy had this covered.

17’ Henry O Hornet w/ Johnson 88 spl

26’ Palmer Scott project hull

14’ Bentz-Craft w/ Yamaha 25

http://www.ulmerboatworks.com

Are you planning on re-foaming the boat??? May I suggest ping pong balls…easier to get out.

Get it man…I like your work ethic.